Your solution for easy and effortless screwing! Made by Wurth for your requirements.

Your solution for easy and effortless screwing! Made by Wurth for your requirements.

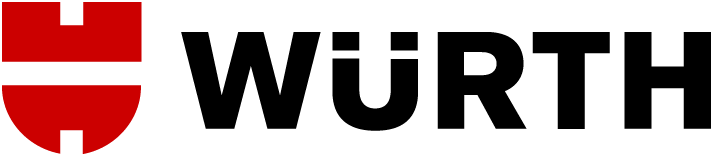

The unique RW Drive System

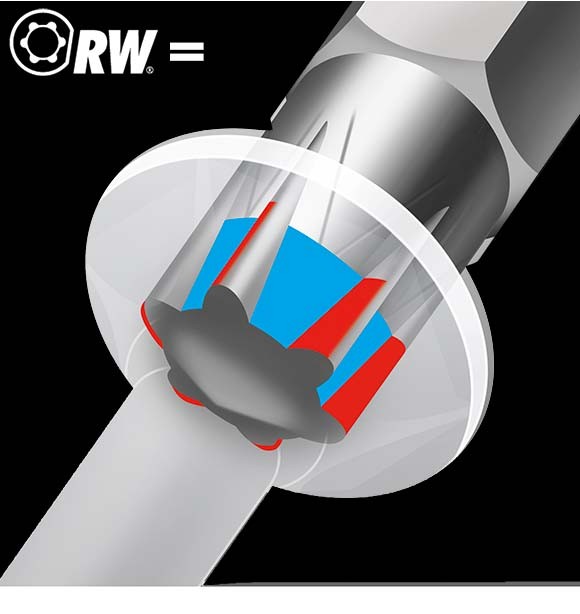

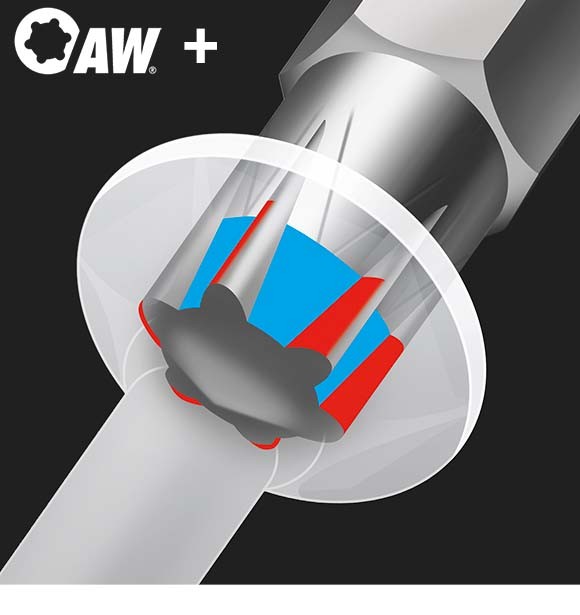

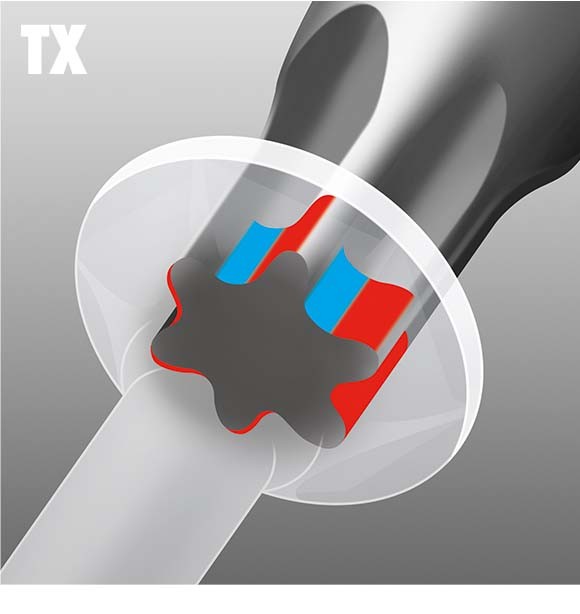

Developing optimal and innovative solutions for our customers’ requirements has always been our focus. As Prof. Reinhold Würth, founder and today’s Chairman of the Supervisory Board of the Wurth Group, strongly believes “We are our customers’ employees”. This attitude was also in mind when the previous AW Drive was engineered many years ago. Combining the advantages of both, Phillips Drive (PH) and Torx Drive (TX), it was the most prestigious drive solution available in the market.

With continuous research and development, combined with the close collaboration with our customers, the previous AW drive solution could be further optimised. The newly designed RW Drive was born – ensuring an even better performance than ever before!

RW Drive vs. Common Drive Types | RW = AW + PH + TX

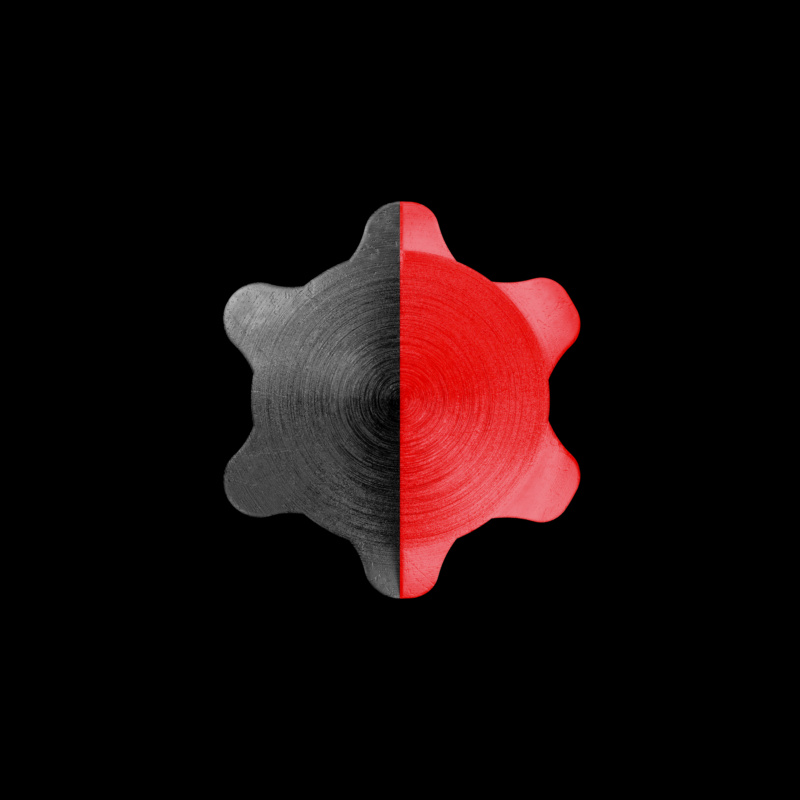

Compared to other common drive types, the RW Drive has more contact points inside the screw head. This ensures easy and effortless screwing. No contact pressure is required, which demonstrates the excellent assembly performance. Moreover, the special drive design avoids damaging the screw coating.

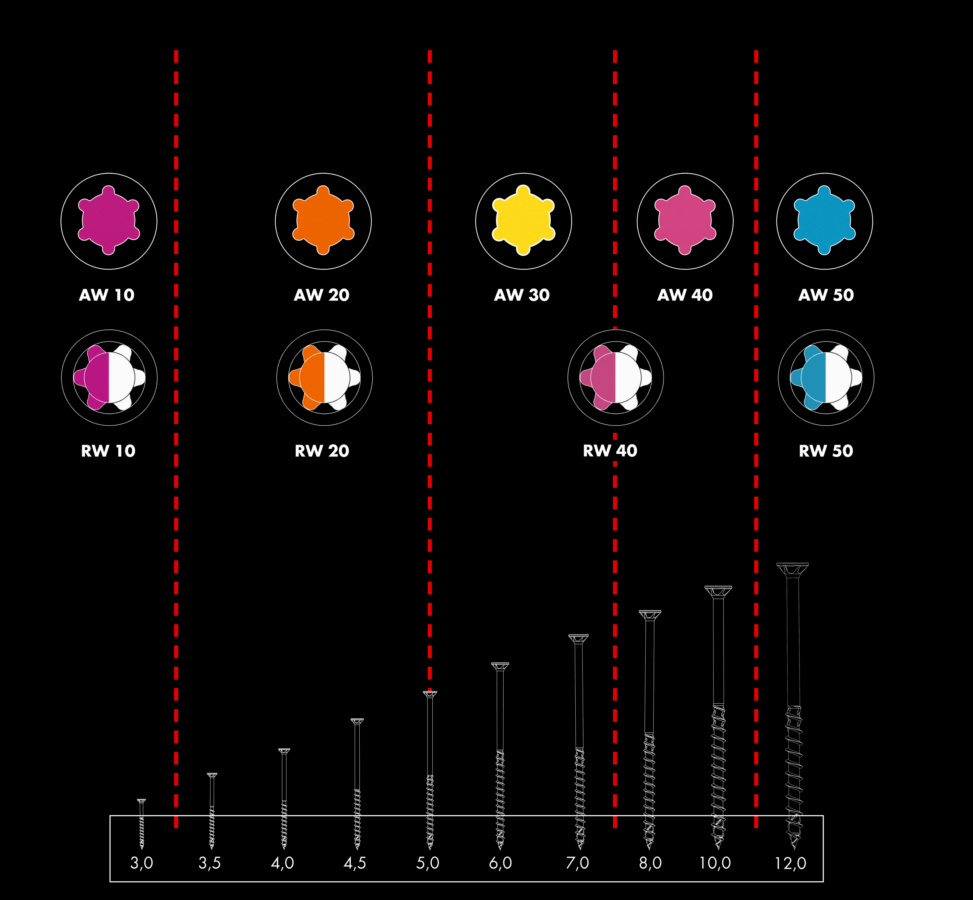

Compared to the AW Drive, the newly designed RW Drive requires fewer bit changes but offers more power and increases performance.

RW Drive in Detail – Fewer bit changes, more power, higher performance!

One RW bit for many screw diameters:

RW Drive & the unique ASSY®4 Screw

The development of the RW Drive was part of the optimisation process of the Wurth ASSY® Timber Screw. Besides the enhanced drive, the new ASSY®4 generation received various feature improvements. Learn more about the ASSY®4

When you view and play embedded videos on www.wurth.com.au, the provider (YouTube) may be able to store your access and analyze your behavior. If you activate the content, i.e. agree to view and play it, a cookie is placed on your computer to record that you have agreed to this in your browser. This cookie does not store any personal data.

For more information, please see our privacy policy and cookie page.

You can also use this link to access the video directly on the plattform of the provider: https://youtu.be/KvUTZ5qutVQ

RW Drive – Voices & Opinions

We use cookies to improve your website experience and for web analytics purposes. By continuing to use our website you agree to our Privacy Policy and the use of cookies as well as our Terms and Conditions and Terms and Conditions - Web & App.